Air Quality Standards

Dust has a significant impact on the health, comfort, and safety of workers and machines in mining, quarrying, construction, and related industries worldwide. The general activities at work produce hazardous airborne particles and gases. To ensure good air quality for operators, governments and organizations have established air quality standards for cabin design, performance, maintenance, operation, and testing methods. These standards and regulations, such as the new international ISO 23875 standard and Australian RS20, prioritize the air quality inside operator cabins.

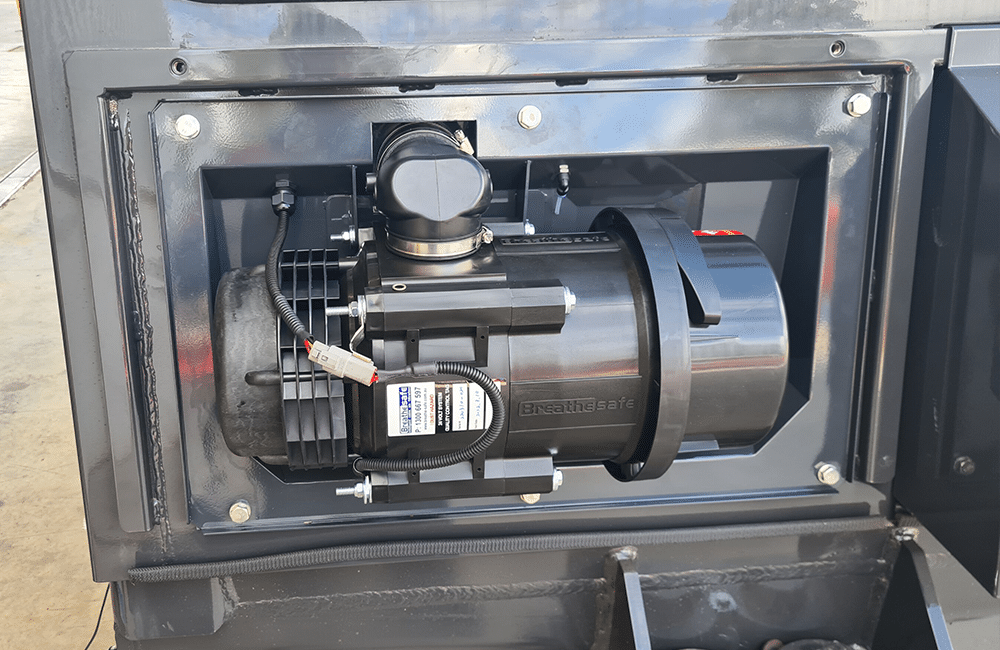

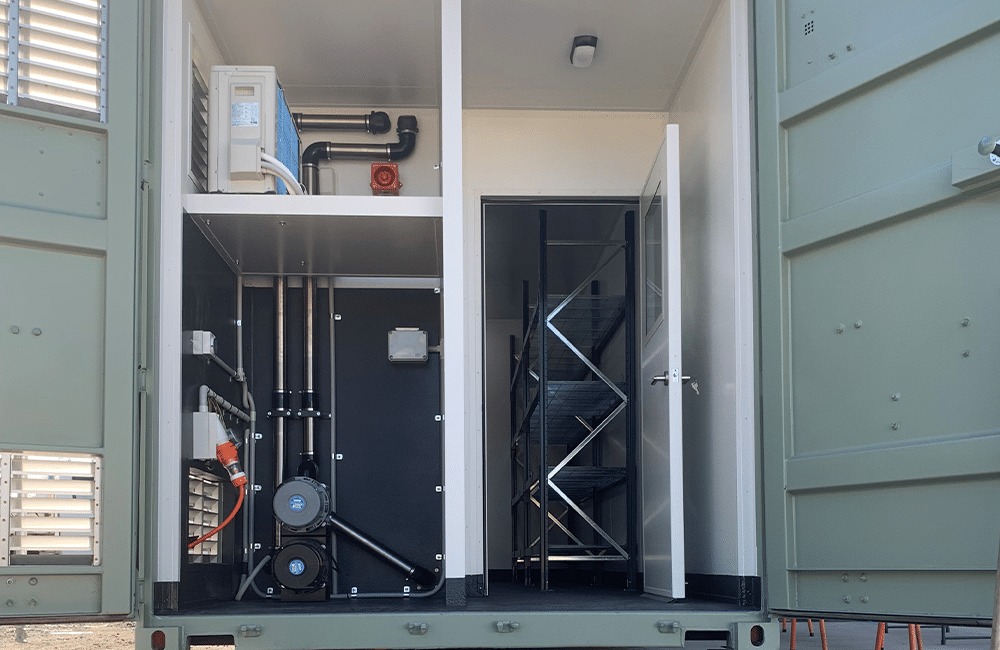

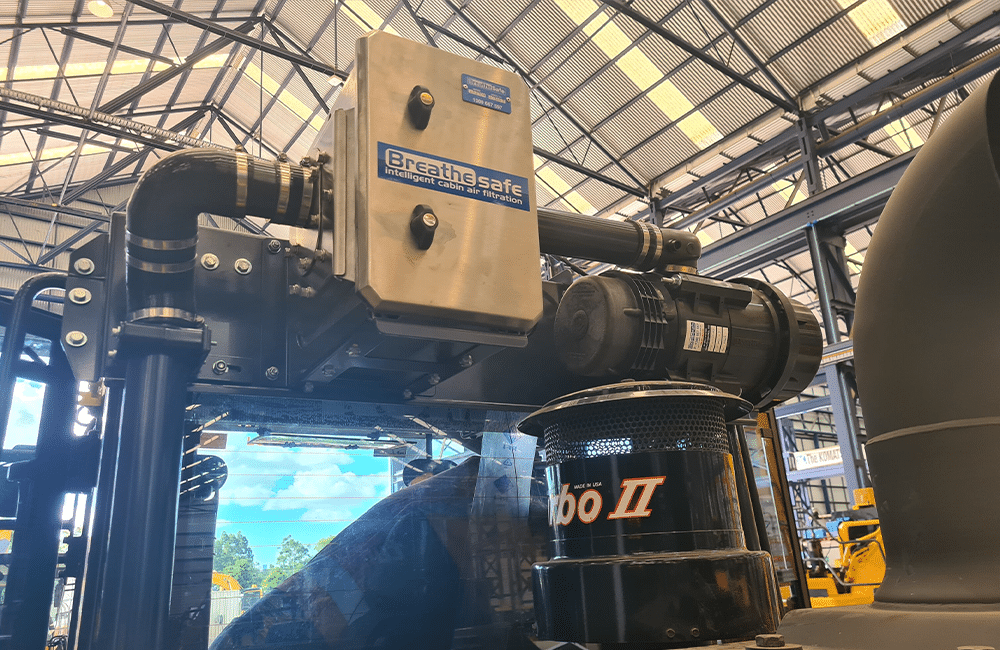

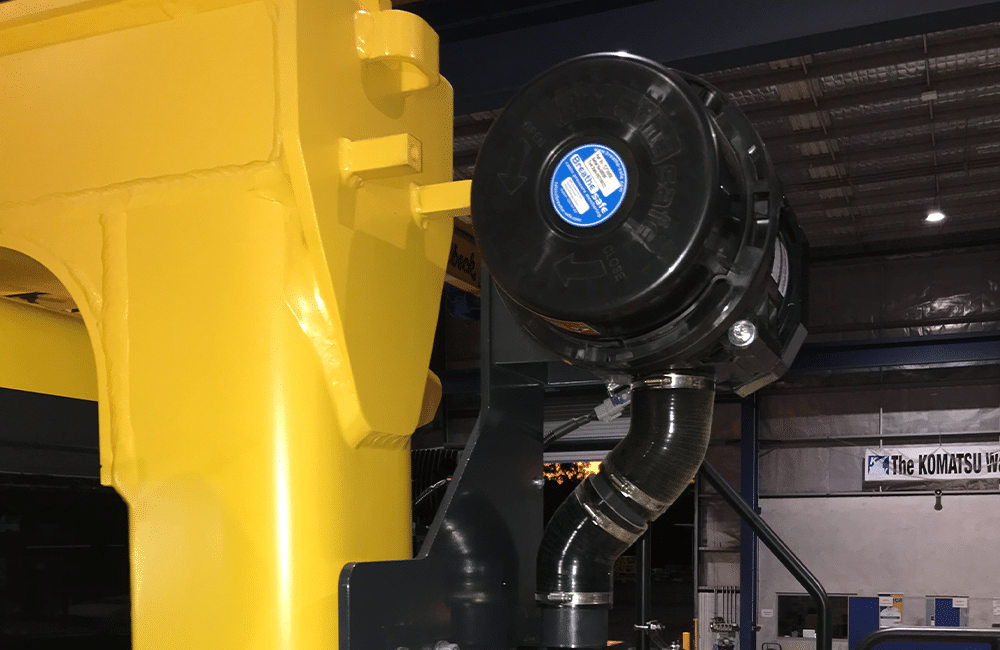

BreatheSafe is here to address these concerns and provide solutions.

International Organization for Standardization

ISO 23875

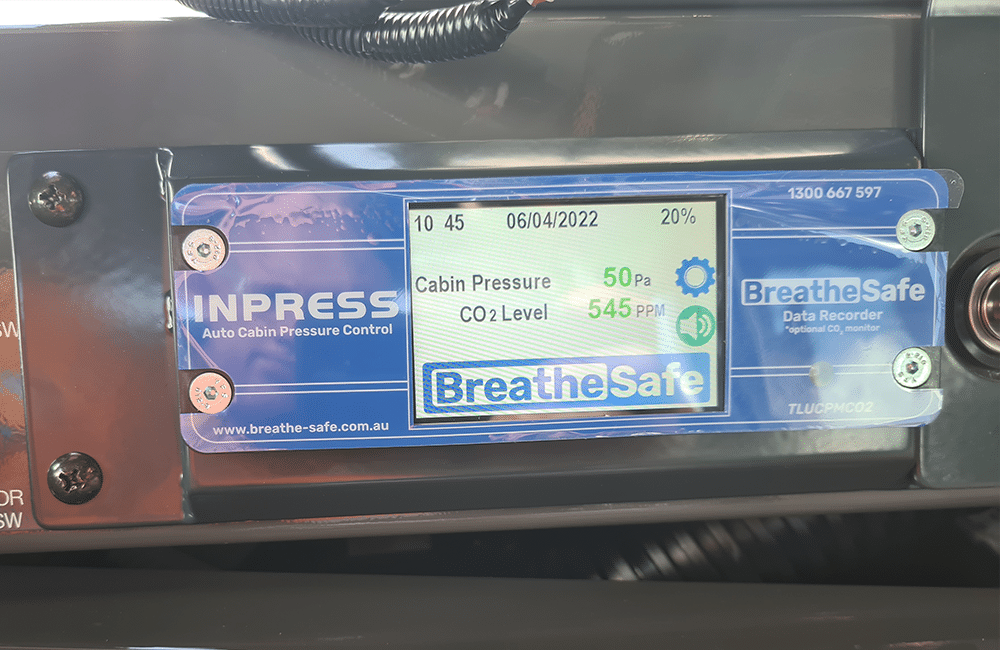

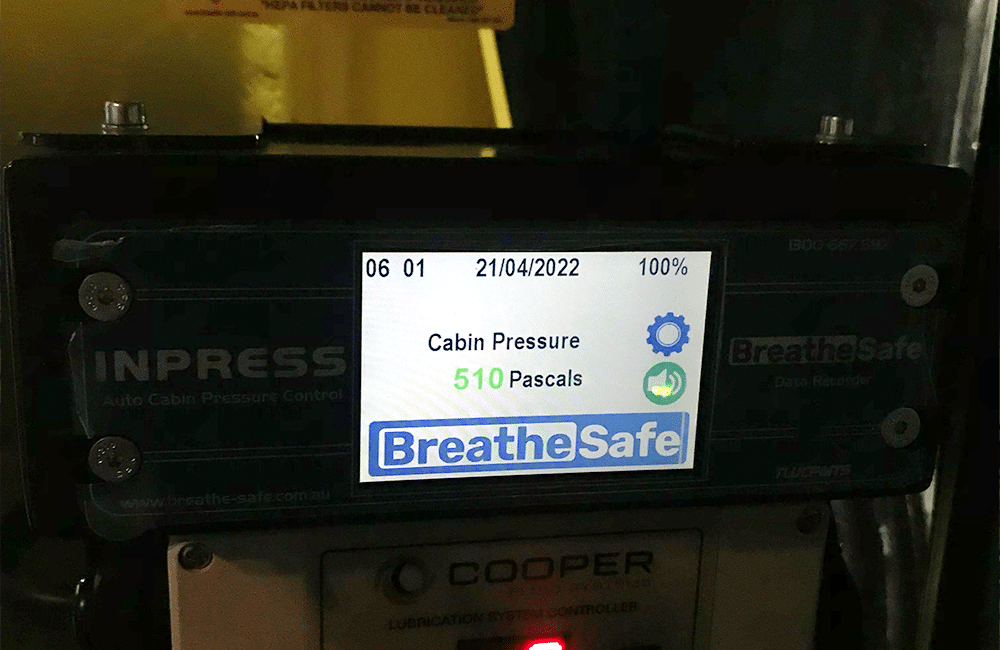

– One of the latest developments in regulations is ISO 23875 for the mining industry. BreatheSafe systems meets and exceeds this standards with our new INPRESS TS.

There are 5 performance requirements in ISO 23875

- Maximum sustained CO2 levels

- Maximum respirable particulate matter

- Speed of particulate matter filtration

- Minimum sustained pressurisation is 20Pa

- Maximum sustained pressurisation is 200Pa

ISO 2021, Link below

ISO 10263

– Earth-moving machinery operator enclosure environment for HVAC.

Prior to the publication of ISO 23875, ISO/TC 127 (ISO Technical Committee 127 – Earthmoving Machinery), had published a standard series which also covered some of the same subject matter.

The performance requirements in ISO 10263:

- Maintaining 50 to 200 Pascals

- Fresh airflow requirement of more than 43m3/hr

- 96% efficiency of external air filter

- Heating system with windscreen defrosting features

- Focus on airflow vs CO2

ISO 2009, Link below

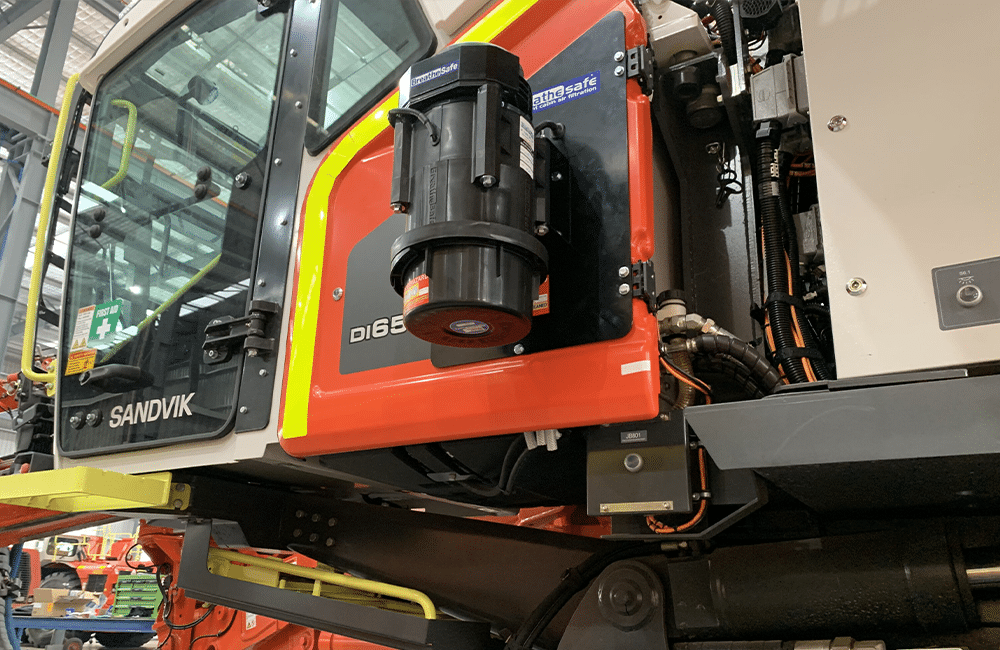

Sample shown Sandvik Drill DL650i Leopard

ISO 29463

– High efficiency filters and filter media for removing particles from air: Classification, performance, testing and marking.

ISO 29463 establishes a procedure for the determination of the efficiency of all filters on the basis of a particle counting method using a liquid (or alternatively a solid) test aerosol, and allows a standardized classification of these filters in terms of their efficiency, both local and overall efficiency,

The filter element shall be designed or marked so as to prevent incorrect mounting.

The filter element shall be designed so that when correctly mounted in the ventilation duct, no leak occurs along the sealing edge.

ISO 2017, Link below

ISO 14644-15

– Clean rooms and associated controlled environments – General control

ISO 14644-15 provides requirements and guidelines for assessing the chemical airborne cleanliness of equipment and materials which are foreseen to be used in cleanrooms and associated controlled environments which are linked to the ISO standard for cleanliness classes by chemical concentration.

ISO 2017, Link below

Sample shown Komatsu Wheel Loader WA270-8

ISO 14698

– Clean rooms and associated controlled environments — Biocontamination control

ISO 14698 establishes the principles and basic methodology of a formal system of biocontamination control (Formal System) for assessing and controlling biocontamination when cleanroom technology is applied for that purpose.

ISO 2003, Link below

Recognised Standard

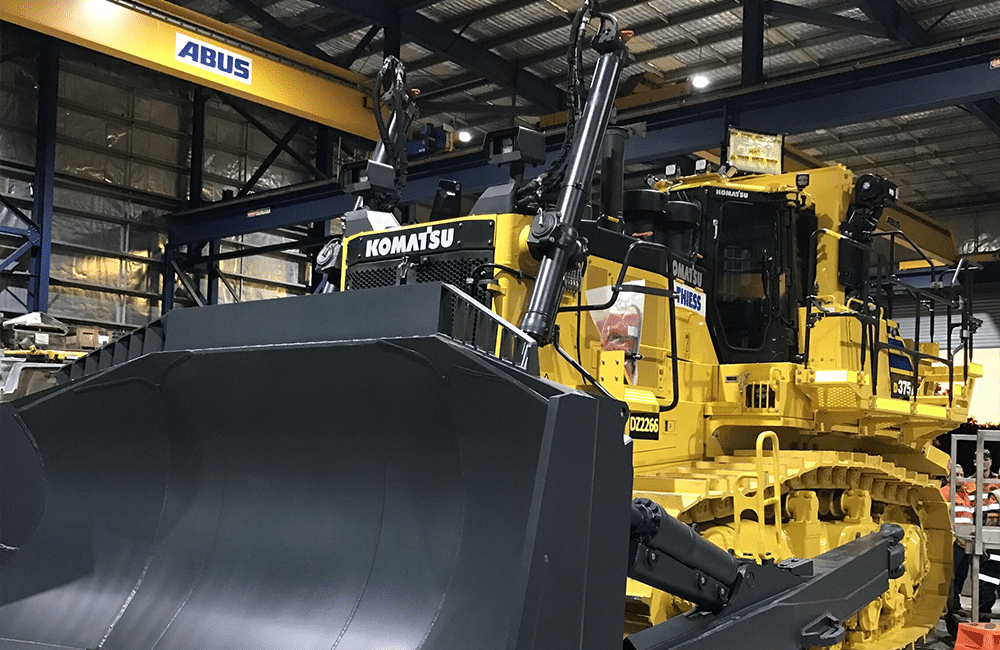

Sample shown Komatsu Dozer D375-8

RS 20

– Dust control in Queensland surface mines.

Generally conventional HVAC systems are not adequate to handle high volumes of dust for long periods of time. It is also likely that standard cabin filters do not sufficiently protect operators from airborne mine dust.

RS20 gives consideration to:

- Filtered air with minimum H13 HEPA filters

- Maintain pressurised cabin at minimum 20Pa

- Continuous monitoring of pressure with auto alarms for events

- Removing dust brought in by operators and use through return air filters and HEPA vacuum systems, with minimum H13 filters

- Ensure effective cabin sealing

- Design of operator cabin for ease of visibility to lessen need to exit vehicle

- Means of ensuring cabin doors remain closed, such as self-closing cabin doors.

- Covering seats in mobile plant with less porous materials to minimise the harbouring of dust.

- Design the cabin to minimise potential for dust accumulations. Position blowers / vents / outlets such that dust is not blown around the cabin (eg from floors).

- Shrouding to minimize latent dust build up above cabin doors.

Queensland Government 2019, Link below

European Standards

Sample shown Komatsu Dozer D375-8

EN 1822

– High efficiency air filters (EPA, HEPA and ULPA) Classification, performance testing, marking.

Key takeaways:

The filter element shall be designed or marked so as to prevent incorrect mounting.

The filter element shall be designed so that when correctly mounted in the ventilation duct, no leak occurs along the sealing edge.

If, for any reason, dimensions do not allow testing of a filter under standard test conditions, assembly of two or more filters of the same type or model is permitted, provided no leaks occur in the resulting filter.

EUROPEAN STANDARD 2019, Link below

Sample shown New Holland T5.95

EN 15695

– Agricultural tractors and self-propelled sprayers – protection of the operator against hazardous substances.

EN15695 is applicable to cabs of agricultural and forestry tractors and self-propelled sprayers. Its purpose is to limit the exposure of the operator (driver) to hazardous substances when applying plant protection products (PPP) and liquid fertilisers. It specifies different categories of cabs of agricultural and forestry tractors and self-propelled sprayers and the relevant requirements and test procedures in order to limit the exposure of the operator (driver) to hazardous substances when inside the cab. It also specifies the information to be provided by the tractor or self-propelled sprayer manufacturer.

EUROPEAN STANDARD 2017, Link below

*This page provides an overview of regulations and should NOT be used as the only source of information.

Please contact us for further information or follow the links to learn more about complying with standards, regulations and guidelines in your area*