Lung Diseases in Heavy Industries: COPD, Silicosis, and More

Lung Diseases in Heavy Industries: COPD, Silicosis, and More

What Are Occupational Lung Diseases?

In heavy industries like mining, construction, and manufacturing, some of the most serious health risks aren’t always visible, and that’s exactly why they’re often ignored. Dust, diesel particulates, and microscopic contaminants may be out of sight, but their long-term impact on lung health is severe and irreversible.

From COPD and silicosis to black lung and progressive massive fibrosis, these diseases can develop silently over years of exposure. By the time symptoms appear, the damage is often permanent.

This article examines the most prevalent lung diseases affecting industrial workers, the symptoms to look out for, and how BreatheSafe’s filtration and pressurisation systems help prevent exposure before it occurs.

Chronic Obstructive Pulmonary Disease (COPD)

Causes narrowing and inflammation of airways, and damages air sacs (alveoli), making it difficult to breathe out.

Symptoms include:

-

Persistent cough with mucus

-

Shortness of breath during physical activity

-

Wheezing or chest tightness

Long-term exposure to fine dust, fumes, and diesel particulates is a major cause in industrial settings.

Silicosis

Caused by inhaling fine crystalline silica dust, commonly found in rock, sand, concrete, and mine dust. Leads to scarring (fibrosis) of lung tissue due to inhaled silica dust, which reduces lung capacity over time.

Symptoms include:

-

Persistent cough

-

Chest pain

-

Shortness of breath

In advanced cases, it may develop into Progressive Massive Fibrosis (PMF), a severe and debilitating condition marked by large scarring of lung tissue.

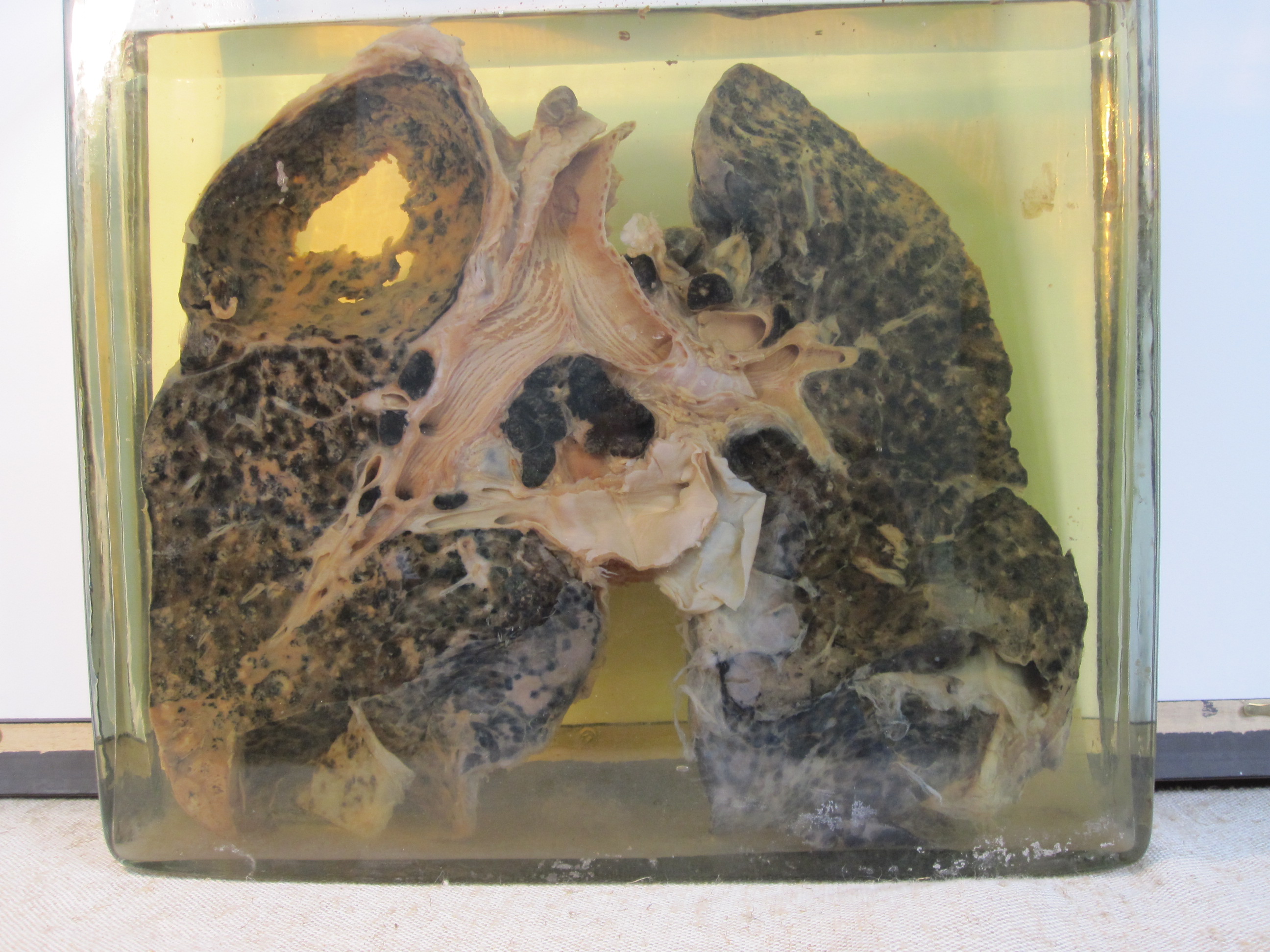

Miner’s lung with silicosis and tuberculosis (Basque Museum of the History of Medicine and Science, Spain)

By Museomed – Own work, CC BY-SA 3.0, https://commons.wikimedia.org/w/index.php?curid=12223787

Black Lung Disease (Coal Workers’ Pneumoconiosis)

Results from long-term inhalation of coal dust and cause the accumulation of coal dust in the lungs, triggering chronic inflammation and fibrosis.

Symptoms include:

-

Chronic coughing

-

Breathlessness

-

Lung scarring

Can progress to Progressive Massive Fibrosis (PMF) in severe or prolonged cases.

Progressive Massive Fibrosis (PMF)

An advanced stage of silicosis or black lung that causes large, severe scars to form in the lungs, leading to major breathing impairment.

Symptoms:

-

Severe, permanent shortness of breath

-

Reduced lung capacity

-

Poor quality of life and limited treatment options

PMF is not a standalone exposure disease but a complication of advanced dust diseases.

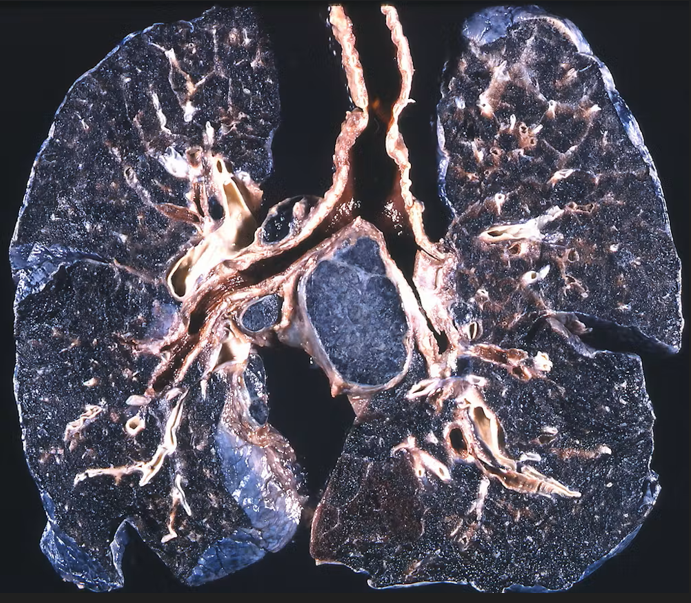

Lung slice from a coal worker, showing black pigmentation and fibrotic scarring caused by prolonged inhalation of coal dust and silica particles.

Dr. Yale Rosen, https://www.flickr.com/photos/pulmonary_pathology/5187845054/, CC BY-SA

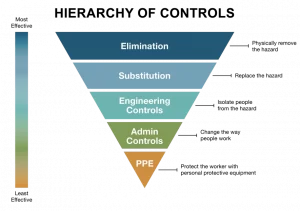

How to Actively Prevent Lung Disease?

Preventing lung disease in industrial environments starts with clean air. Using high-efficiency filtration systems like HEPA H14, maintaining positive pressure in cabins and rooms, and monitoring air quality in real time are key steps. These measures help reduce workers’ exposure to harmful dust and gases, lowering the risk of long-term conditions such as COPD, silicosis, and black lung.

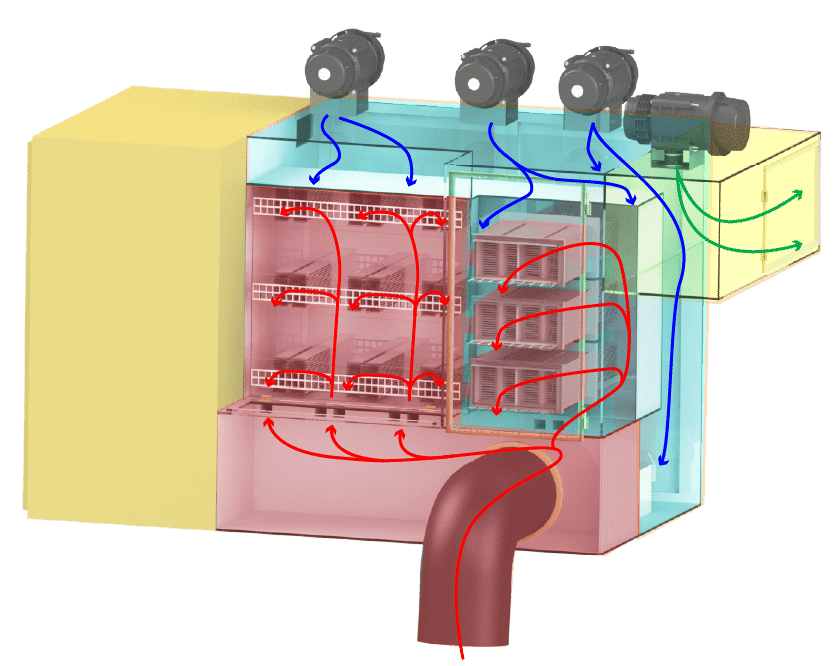

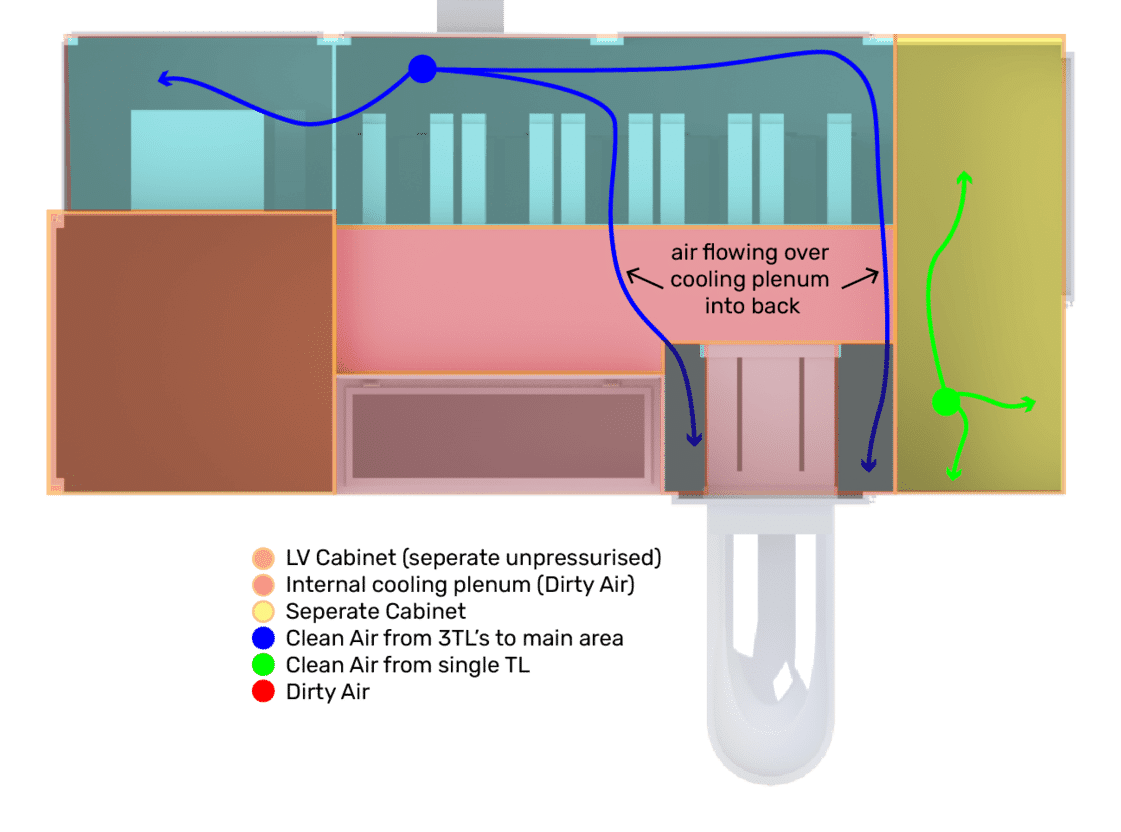

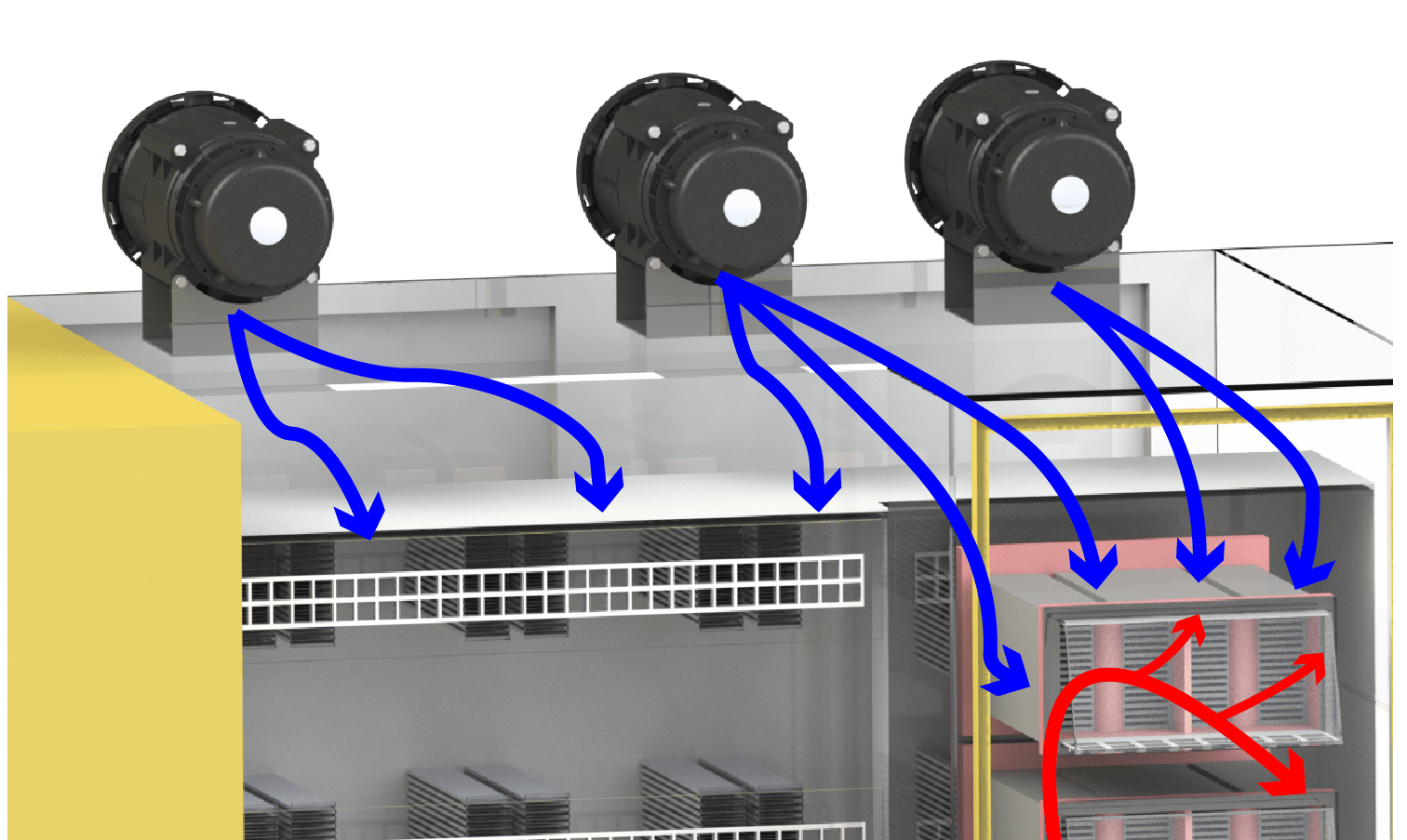

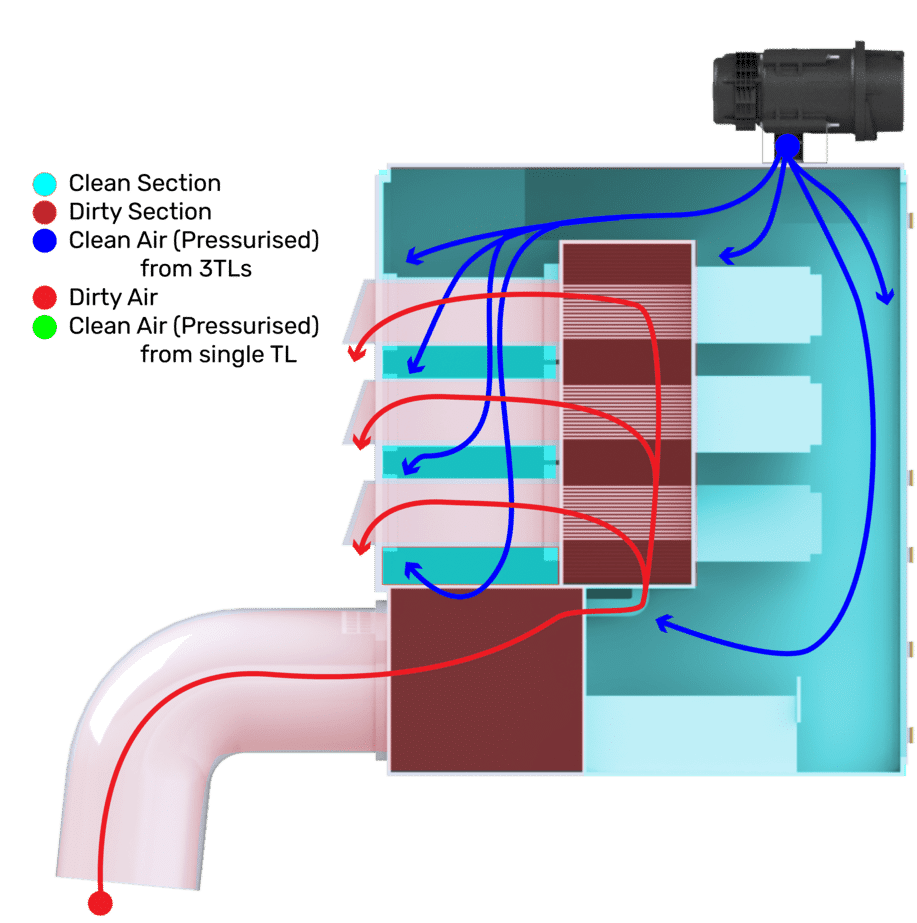

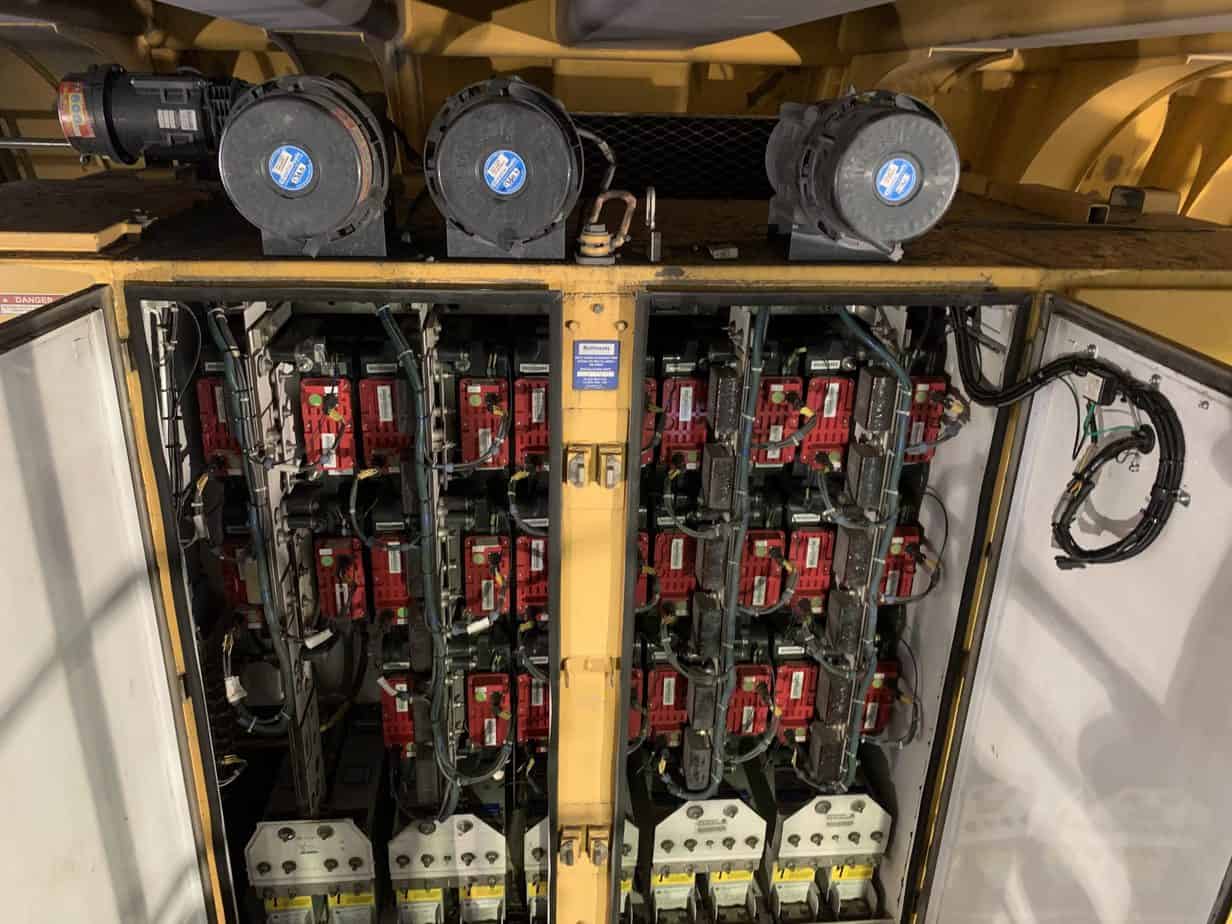

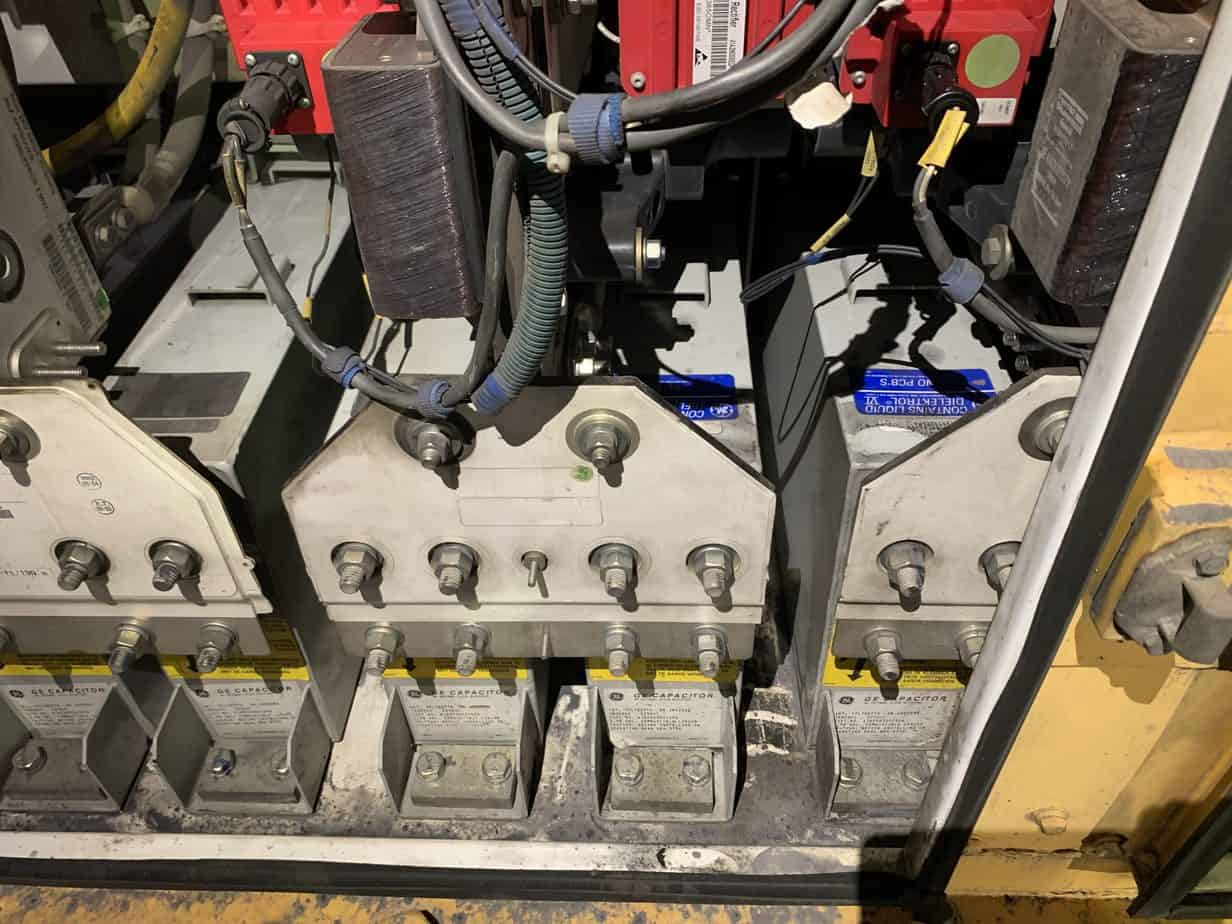

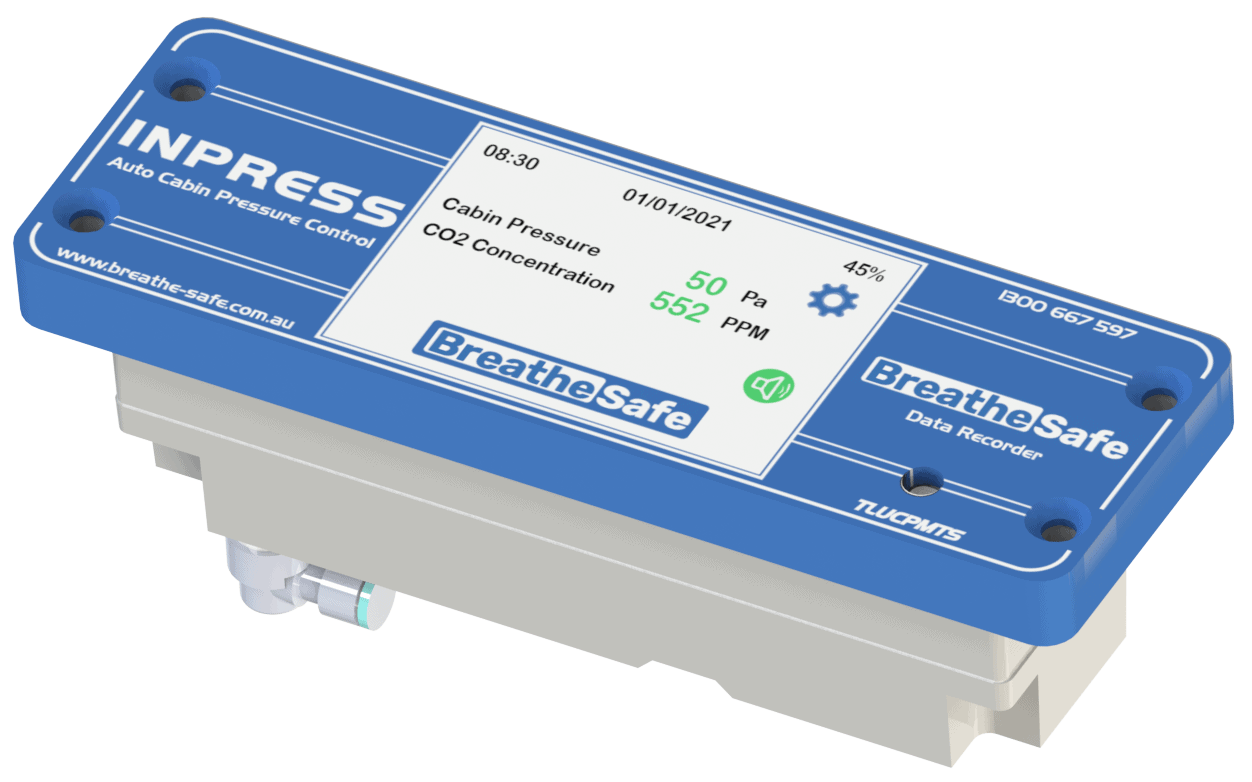

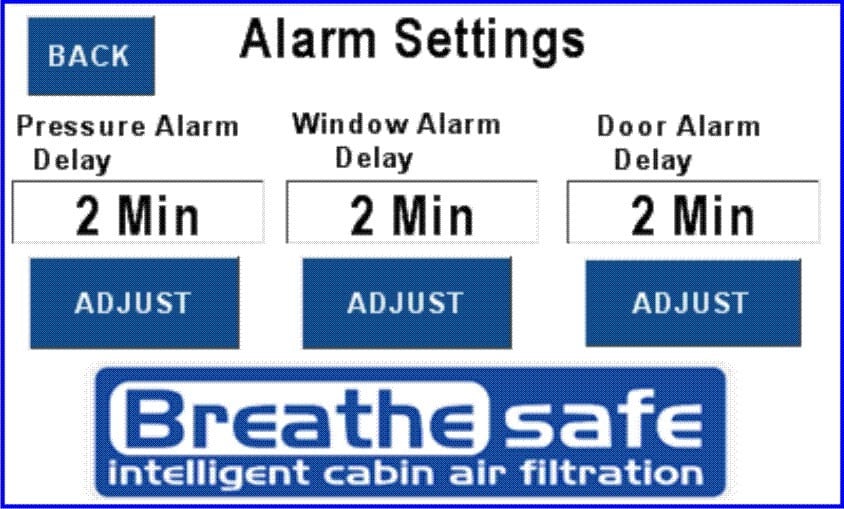

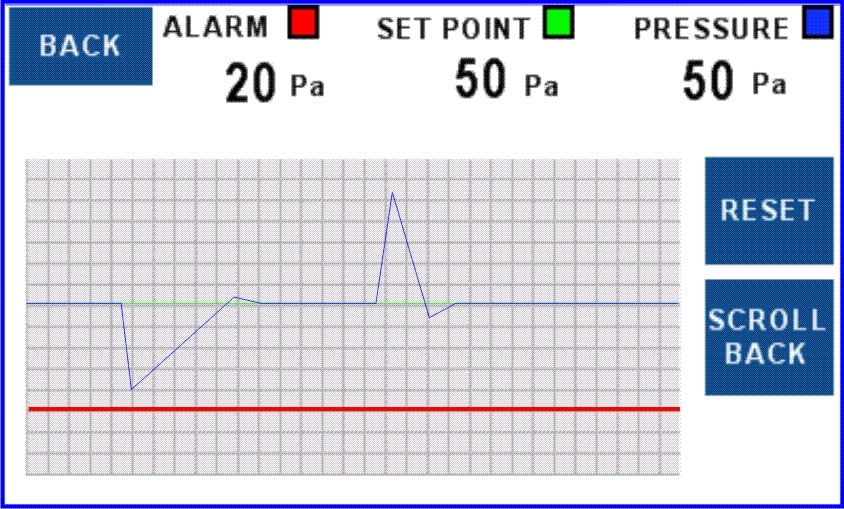

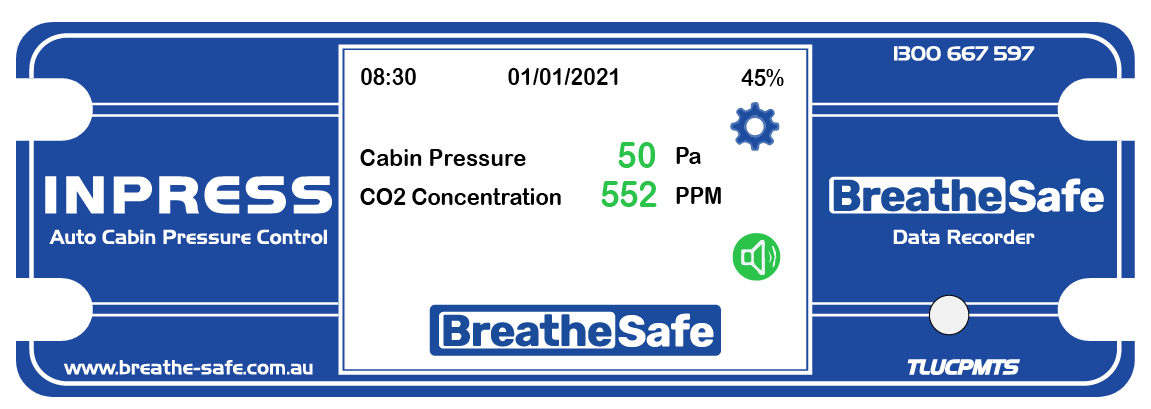

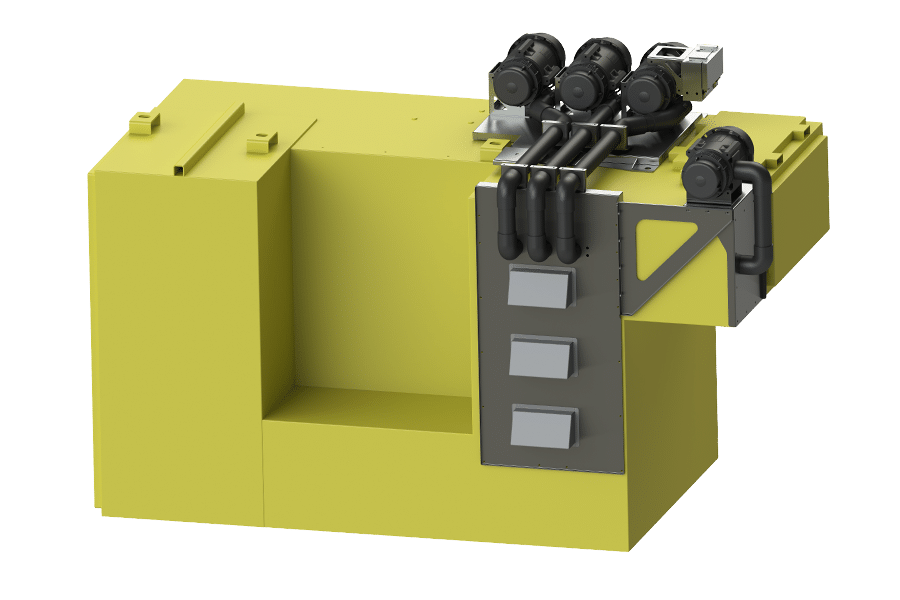

Operator Cabins – BreatheSafe System

What it does:

BreatheSafe system filters and pressurises air in mobile machinery like excavators, dozers, trucks, and drills.

Key features:

-

HEPA H14 filtration removes 99.995% of harmful dust (carbon filter optional for gas removal)

- HEPA Panel Return Air Filter scrubs and filters the internal air

-

Positive pressure keeps contaminants out

-

Real-time monitoring of CO₂, PM2.5, airflow, and cabin pressure

Why it matters:

It protects machine operators at the source of exposure and helps your site meet safety standards for air quality.

BreatheSafe system fitted to a JCB loader 436HT

Enclosed Workspaces – RoomSafe System

What it does:

RoomSafe protects crib rooms, control rooms, and workshops from harmful dust and gases.

Key features:

-

HEPA H14 pressuriser filters incoming air (optional carbon module for gas removal)

-

Positive pressure prevents contaminated air from entering

-

Power HEPA recirculation filter captures internal dust and improves airflow.

Why it matters:

RoomSafe creates a clean-air zone where workers can safely rest, work, and recover — even in high-dust environments.

RoomSafe system fitted to a TBM control room

Conclusion: Dust Is Invisible — But the Risk Isn’t

Diseases like COPD, silicosis, black lung, and progressive massive fibrosis develop over time, often with no early symptoms. But by the time they’re diagnosed, the damage is often permanent. Fitting a proper air filtration and pressurisation system is one of the most effective ways to reduce workers’ exposure to harmful dust and airborne contaminants. When combined with real-time air quality monitoring and regular maintenance, these systems help create safer breathing environments, whether in machine cabins or enclosed workspaces. This not only protects worker health but also helps sites comply with modern occupational air quality standards.