Advanced Protection for Sensitive Electronics

Protect sensitive electronics by maintaining a dust-free and temperature-monitored environment.

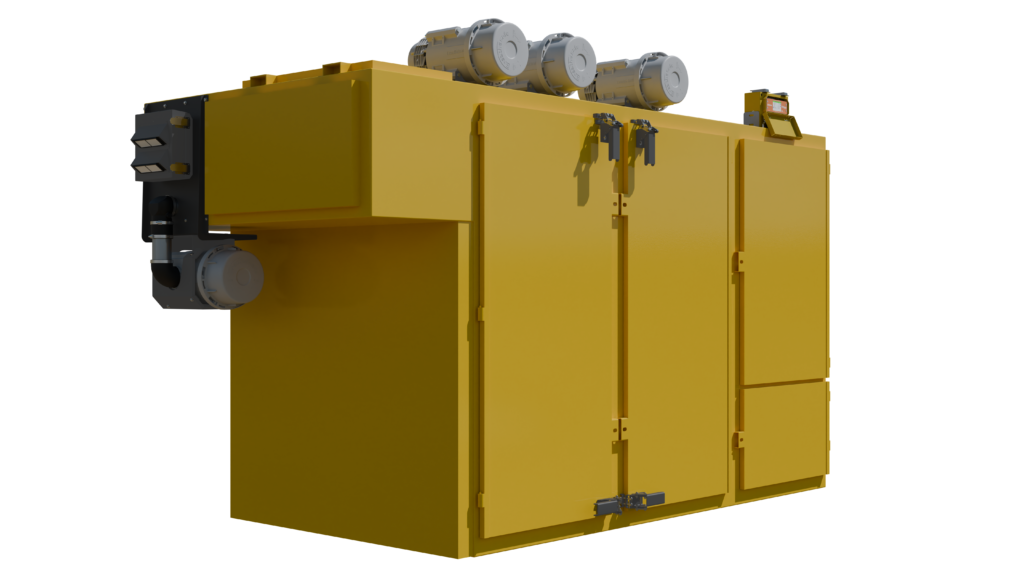

Komatsu 830E-4 Electrical Cabinet

VoltAire for Electrical Enclosure

Eliminates the Need for Regular Cabinet Cleaning

High-Pressure Filtration Technology

VoltAire utilises advanced high-pressure filtration technology, generating positive pressure inside the cabinet to ensure that only filtered air enters, creating a clean and controlled environment.

Reduce Maintenance and Enhance Safety

This innovative design eliminates the need for regular cleaning, reduce maintenance costs and protects workers from exposure to hazardous dust and potential arc flash.

Applications

- High-Voltage Cabinets – Require protection from dust and moisture to prevent electrical arcing, insulation breakdown, and equipment failure.

- Low-Voltage Cabinets – Need a clean and controlled environment to ensure stable performance and prevent disruptions in sensitive electronics.

- Motor Control Cabinets – Must remain free from dust accumulation on contactors and relays, which can cause malfunctions, overheating, and reduced operational efficiency.

- Distribution Boards – Require protection to prevent short circuits, corrosion, and electrical faults, ensuring system reliability and longevity.

- Contactor Cabinets – House delicate switching mechanisms that can degrade if exposed to dust, moisture, or airborne contaminants, leading to frequent maintenance and increased safety risks.

- Switchboard Cabinets – Must be kept free from dust and temperature fluctuations to minimize downtime, reduce failures, and maintain uninterrupted electrical performance.

Products

Caterpillar 796AC Electrical Cabinet

Pressurise the cabinet with clean and cool air

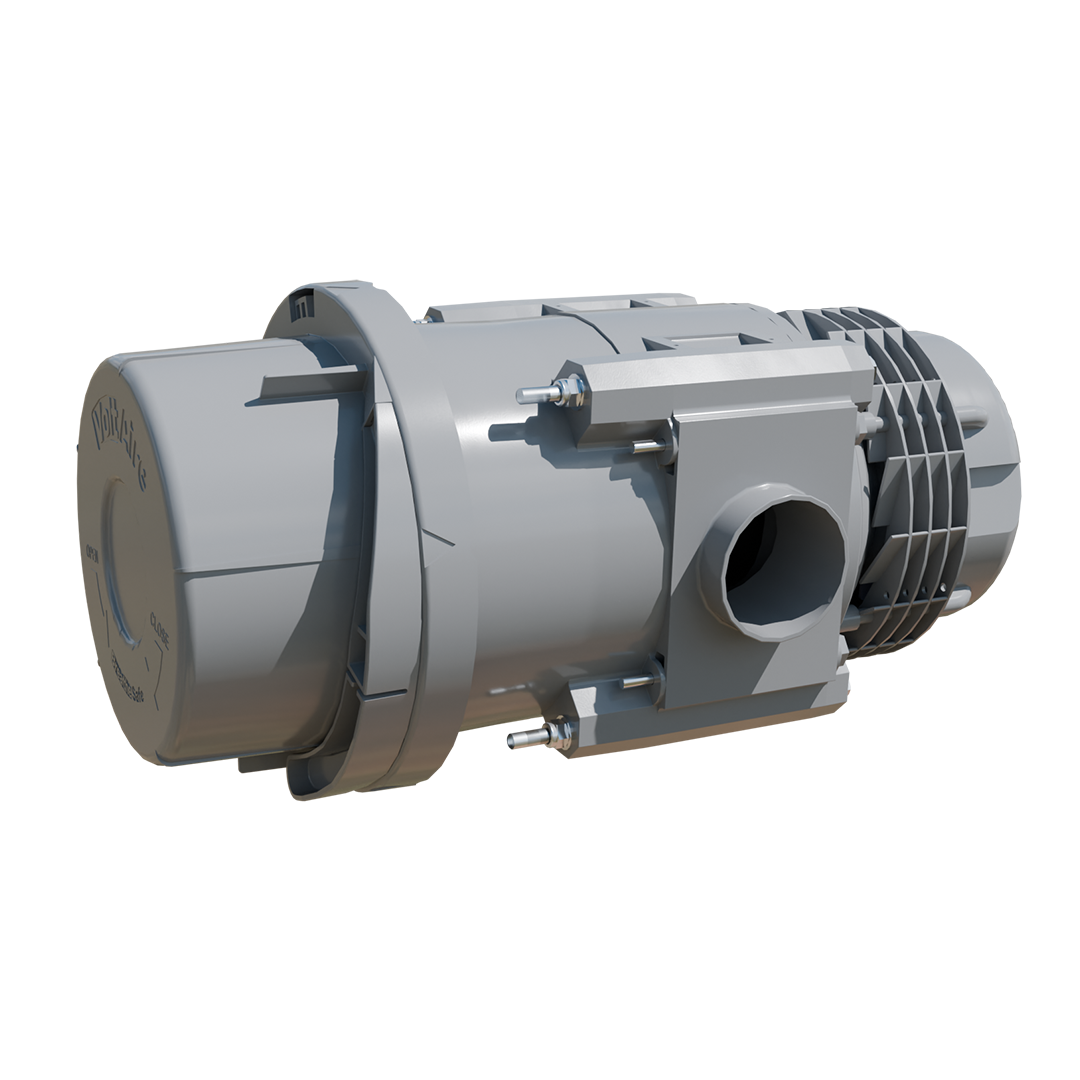

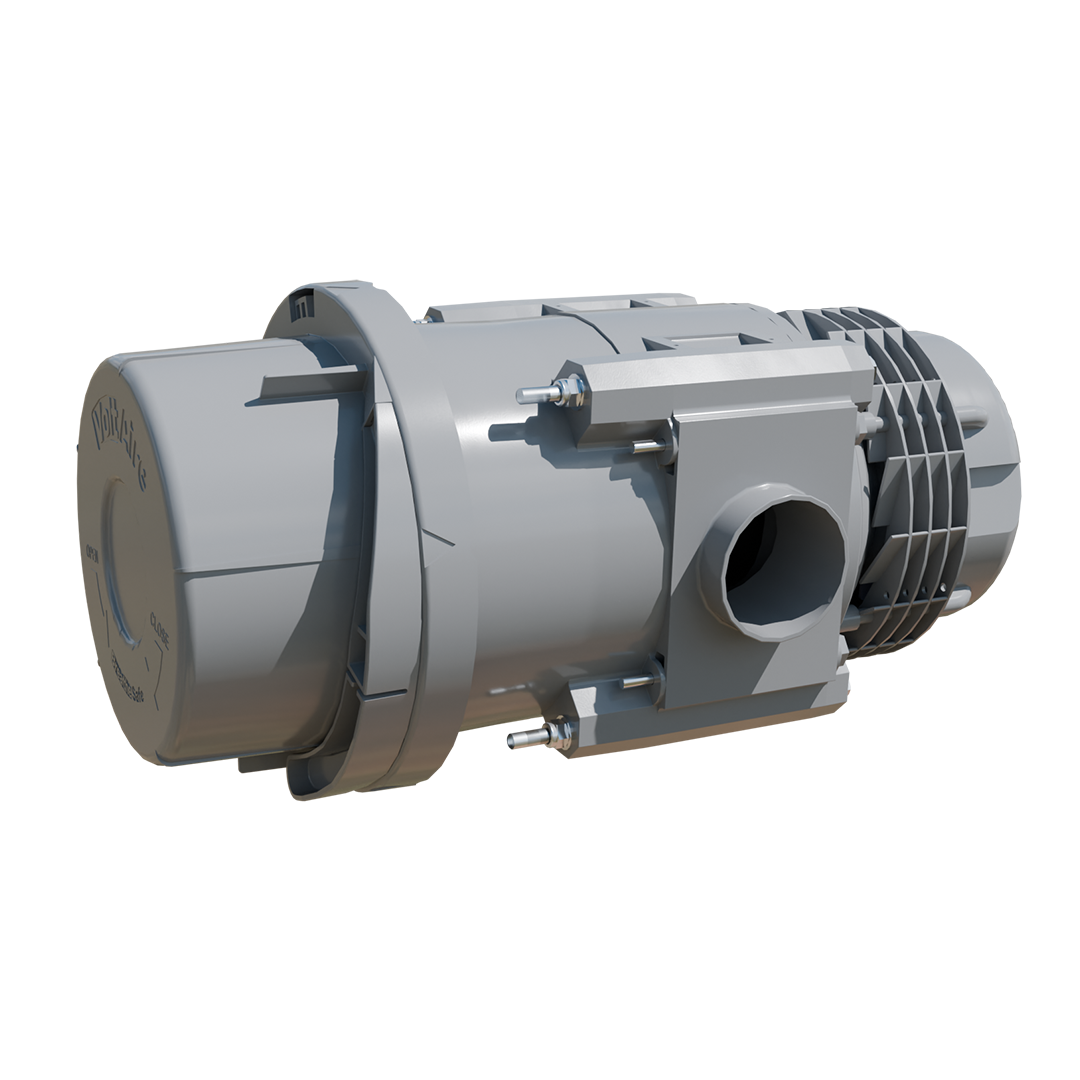

High-Pressure Air Pressuriser

Air Quality Controller

Sensor Pod

Applications

- High-Voltage Cabinets – Require protection from dust and moisture to prevent electrical arcing, insulation breakdown, and equipment failure.

- Low-Voltage Cabinets – Need a clean and controlled environment to ensure stable performance and prevent disruptions in sensitive electronics.

- Motor Control Cabinets – Must remain free from dust accumulation on contactors and relays, which can cause malfunctions, overheating, and reduced operational efficiency.

- Distribution Boards – Require protection to prevent short circuits, corrosion, and electrical faults, ensuring system reliability and longevity.

- Contactor Cabinets – House delicate switching mechanisms that can degrade if exposed to dust, moisture, or airborne contaminants, leading to frequent maintenance and increased safety risks.

- Switchboard Cabinets – Must be kept free from dust and temperature fluctuations to minimize downtime, reduce failures, and maintain uninterrupted electrical performance.

Caterpillar 796AC Electrical Cabinet

Pressurise the cabinet with clean and cool air

Products

High-Pressure Air Pressuriser

Air Quality Controller

Particulate Sensor Pod

Mechanism

Pressurise The Cabinet To Prevent Dust Ingress

Positive pressure ensures only filtered air enters, blocking dust and contaminants. This prevents buildup on critical components, reducing maintenance and extending equipment life.

A HEPA panel filter on the outlet keeps air clean even when the machine is off, further enhancing protection and worker safety.

Air Quality Controller Monitors The Air

Our BreatheSafe controllers monitor air quality in real time, eliminating manual inspections and reducing dust exposure. By analysing particulate levels, pressure, and temperature, they provide insights to optimize performance and component longevity.

For added protection, the VoltAire OnGuard controller features a high dust concentration flush, purging contaminants with clean air when needed. This also helps regulate temperatures, preventing overheating of sensitive electronics.

Mechanism

Pressurise The Cabinet To Prevent Dust Ingress

Positive pressure ensures only filtered air enters, blocking dust and contaminants. This prevents buildup on critical components, reducing maintenance and extending equipment life.

A HEPA panel filter on the outlet keeps air clean even when the machine is off, further enhancing protection and worker safety.

Air Quality Controller Monitors The Air

Our BreatheSafe controllers monitor air quality in real time, eliminating manual inspections and reducing dust exposure. By analyzing particulate levels, pressure, and temperature, they provide insights to optimize performance and component longevity.

For added protection, the VoltAire OnGuard controller features a high dust concentration flush, purging contaminants with clean air when needed. This also helps regulate temperatures, preventing overheating of sensitive electronics.

Case Study

The first trial system has been in service for over 4 years. Now over 5,000 hours on the same filters, the cabin has not required cleaning since the system was installed.

Komatsu 830E HV Field Trial

HV cabinets use unfiltered air from the alternator fan to cool the heat sinks on the inverters, allowing mine dust to enter and accumulate, requiring frequent cleaning and exposing maintenance staff to hazardous dust.

To eliminate this risk and reduce worker exposure, we collaborated with a customer to develop a specialised system that prevents dust ingress, ensuring a cleaner, safer, and maintenance-free solution.

Problem

- Exposure to high concentrations of respirable dust will lead to severe irreversible lung diseases such as silicosis.

- Cabinets are subject to unfiltered air introduced via the alternator fan to cool heat sinks.

- Hazardous dust is forced through unsealed duct seams / deteriorated component gaskets into the main compartment requiring maintenance and cleaning.

- Cleaning of these compartments typically occurs every 500 hours and presents the risk of hazardous dust exposure to workers.

Designed Solution

- Cabinets have been cleaned out before installation.

- The Main HV cabinet has been fitted with 3 High-Pressure TL units.

- Arc Shoe cabinet has 1 standalone High-Pressure TL unit.

- These systems are variable speed pressurisation and HEPA H14 filters.

- Max pressure achieved with the engine off: 1200 Pa above ambient.

- Auto pressure setpoint at 400 Pa above OEM engine-driven fan pressure.

- TL units force air into HV cabinets creating positive pressure.

Achievement

- Cleaning with compressed air has ceased/worker exposure to mine dust diminished!

- The cabinet is maintaining a significantly reduced dust load.

- Internal temperature maintained relevant to ambient.

- Components/wiring easily visible for fault finding.

- Minimised static dust on components – Extended component life.

- Heavily reduced downtime for maintenance/repair costs.

- The system has been inspected at 1000, 1500, 2230 and 2800 hours and is still running the original filters.

- System capacity maintains a 57% load with no drop in sealing efficiency after 3715 hours.

- Max pressure test dropped 390 Pa to a total of 810 Pa– consistent with filter loading/truck voltage & door seals.

Media

VoltAire System Explanation

OnGuard Remote Controller

Filter Replacement Guideline

Other Solutions

Operator Cabin Pressurisation

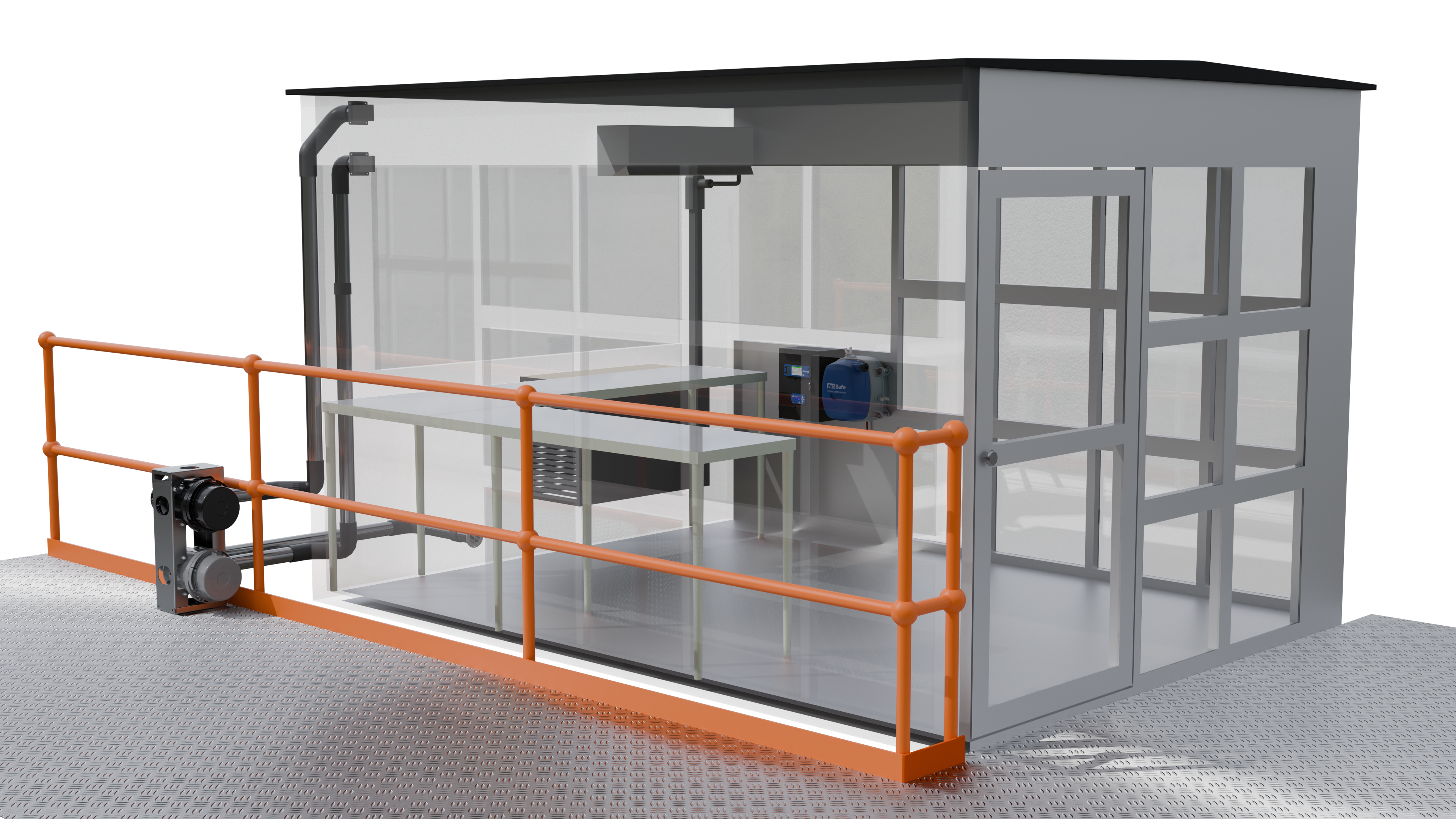

Clean Room Pressurisation

Build Your Own