BreatheSafe News

Discover the latest technology in the industry

2025

12/06

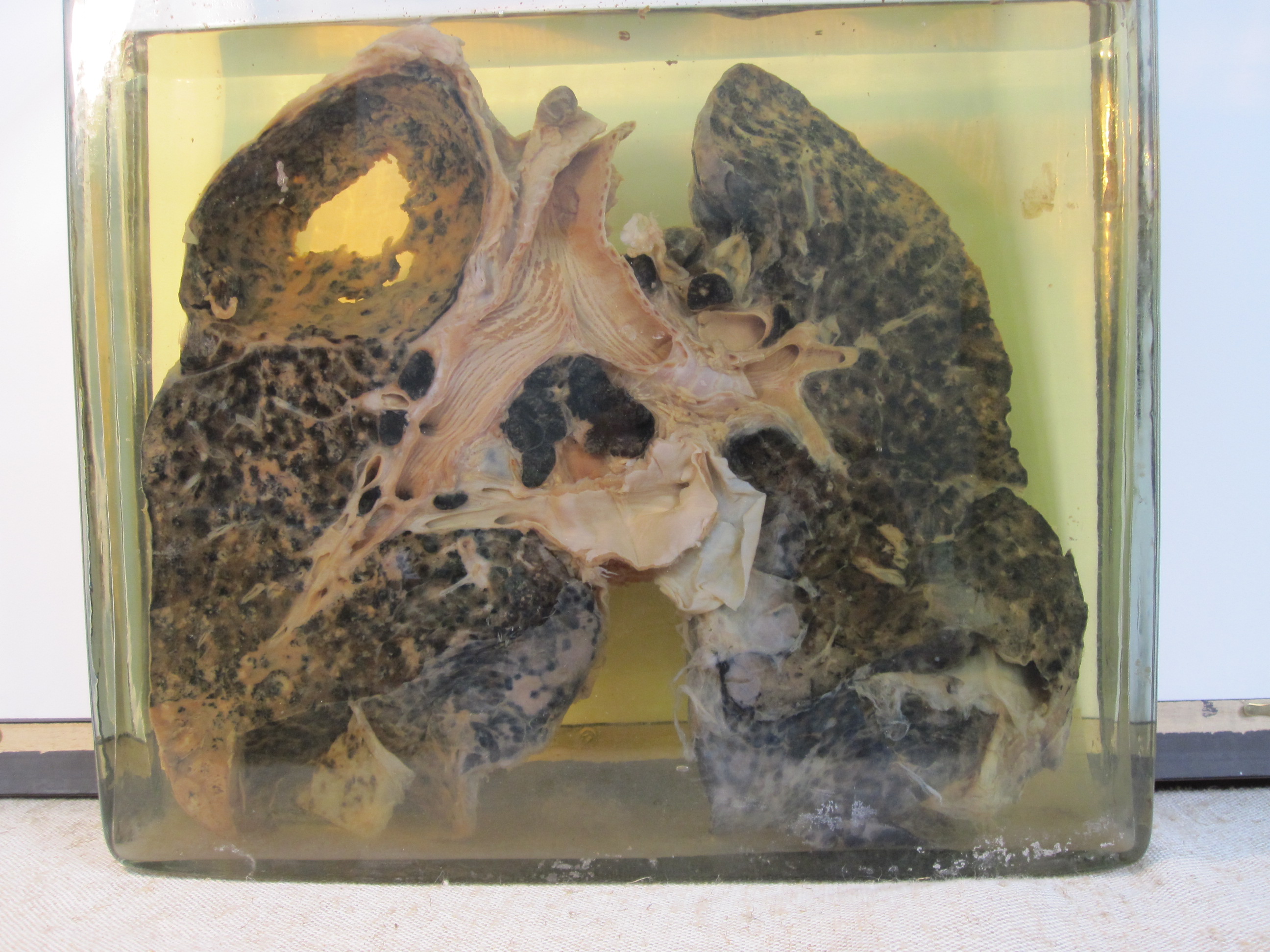

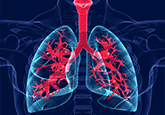

Lung Diseases in Heavy Industries: COPD, Silicosis, and More

2025

07/04

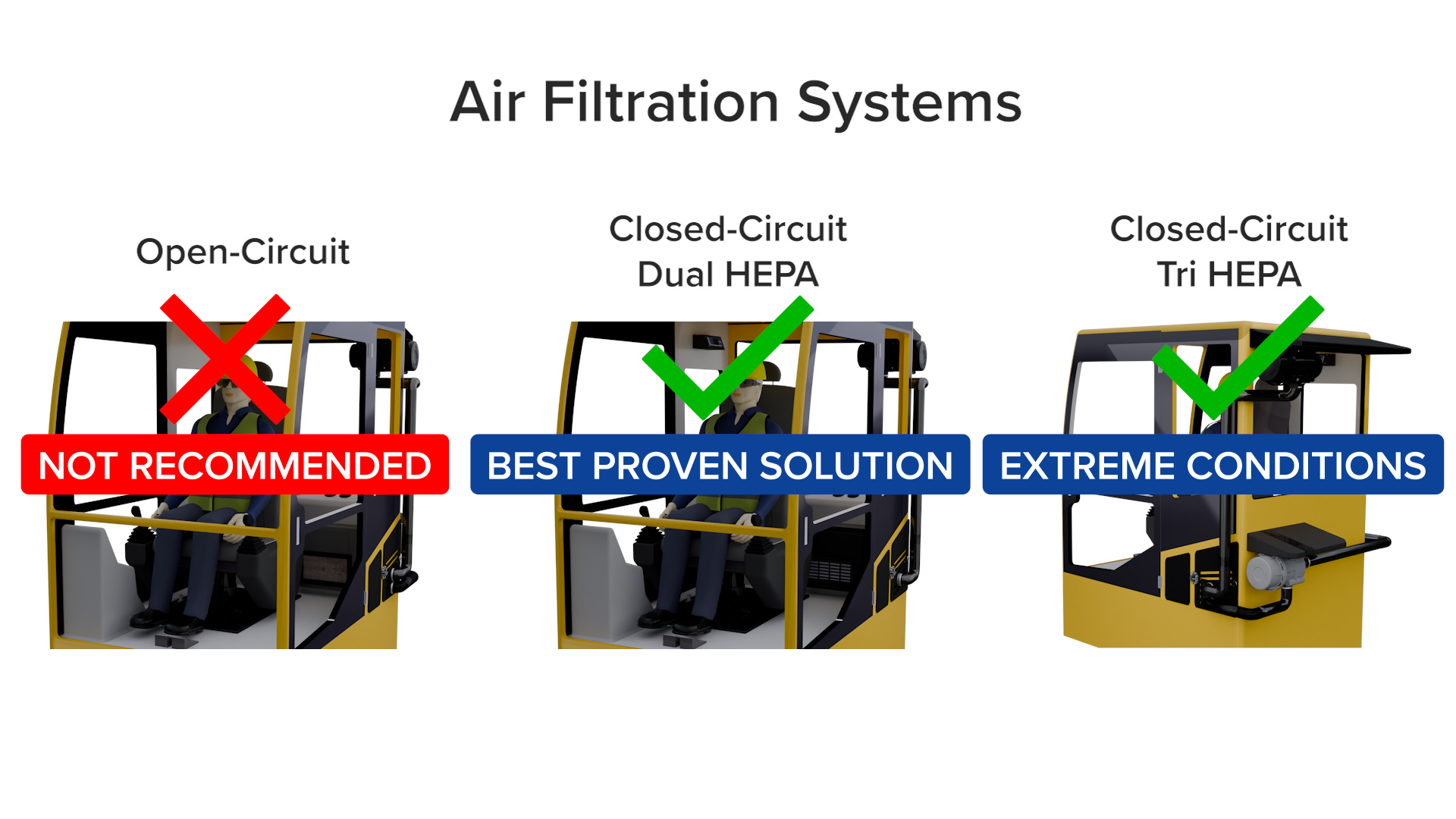

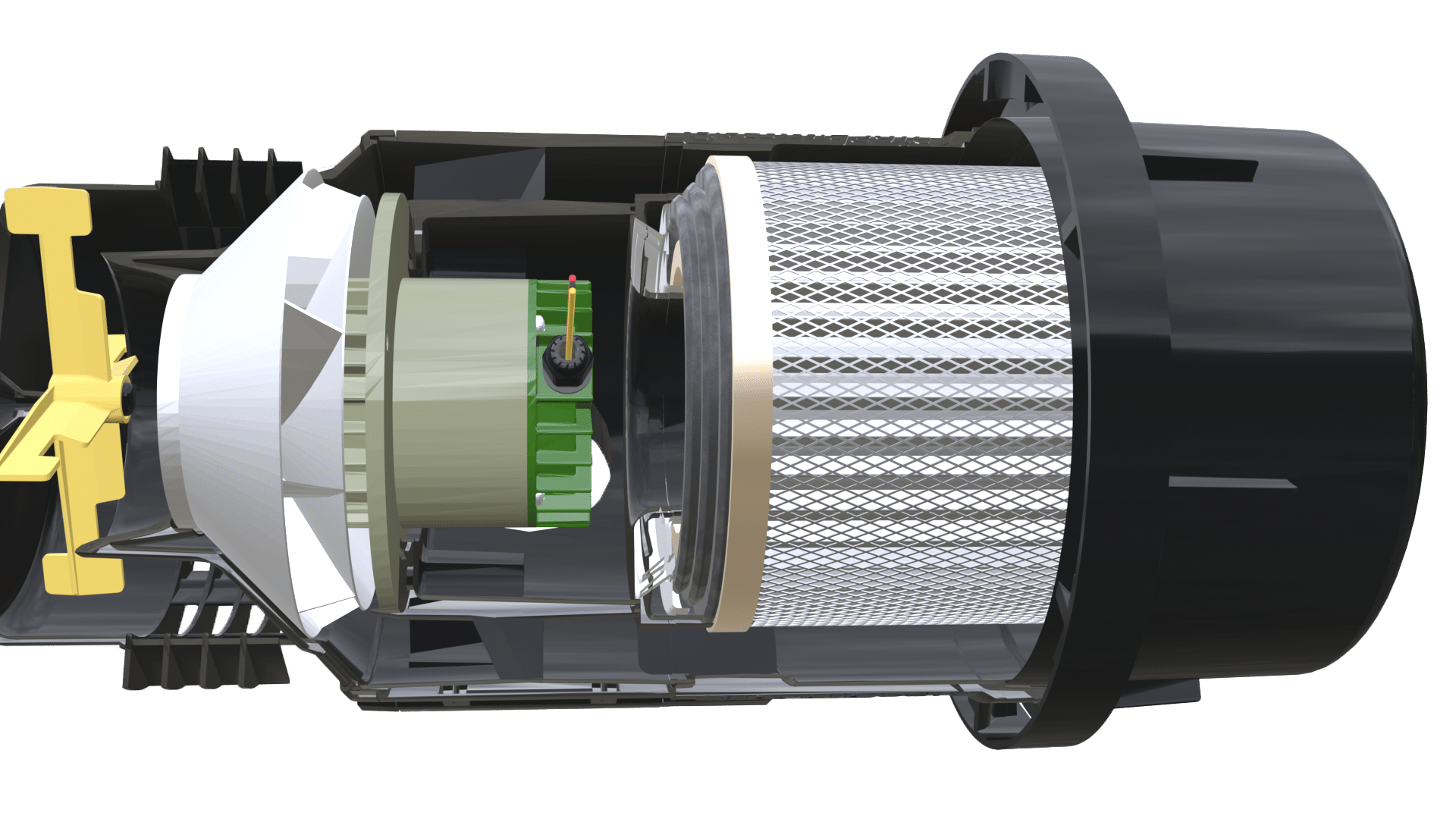

Comparing Filtration Systems: What is the BEST?

2025

07/04

BreatheSafe at the Underground Operators Conference

2024

11/09

Product Video – OnGuard Air Quality Manager

2024

11/09

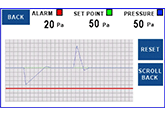

Product Video – InPress Pressure Monitor

2024

11/09

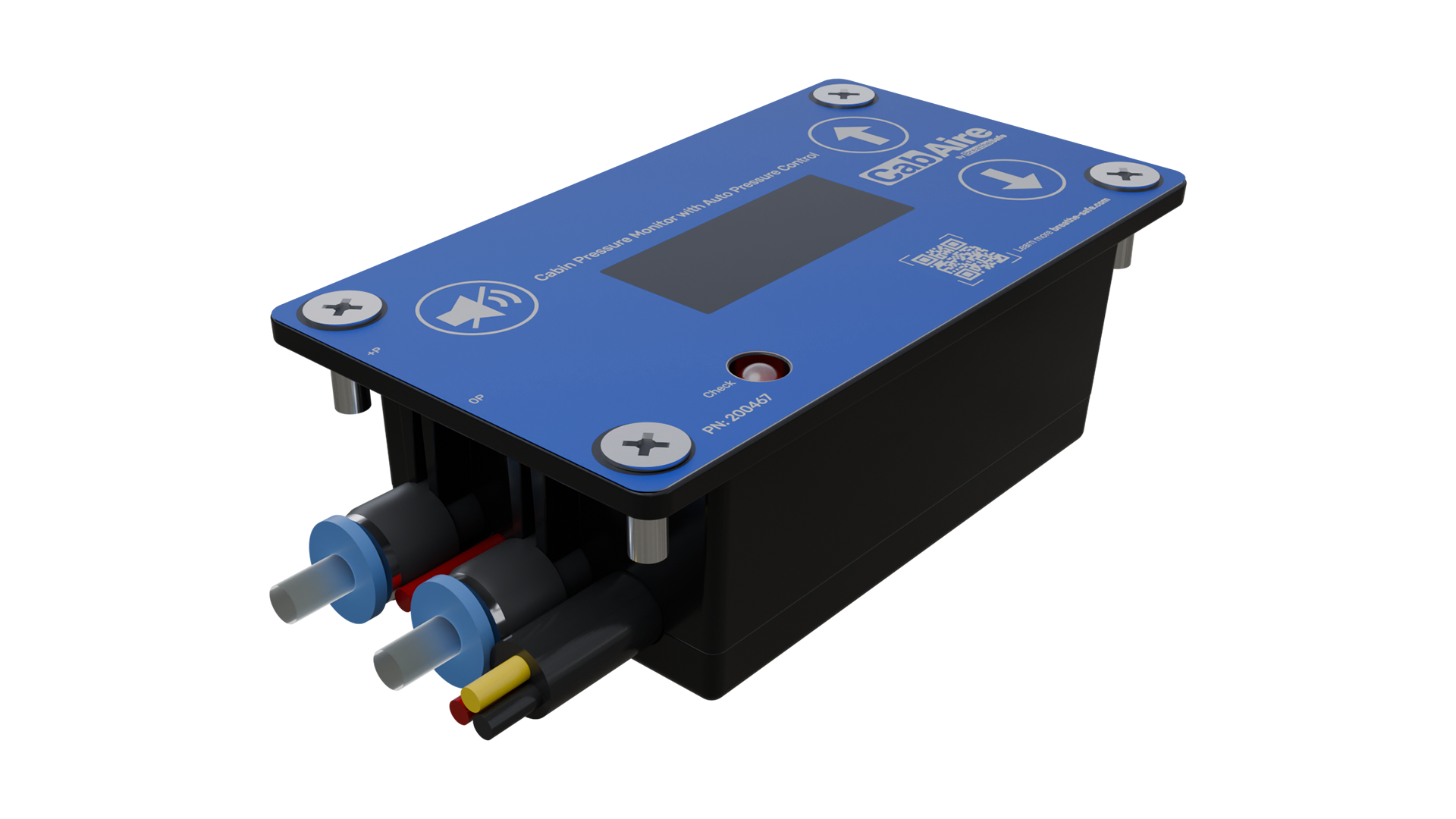

Product Video – CabAire Pressure Monitor

2024

21/08

Queensland Mining Industry Health & Safety Conference

2024

12/02

BreatheSafe Cares – Soiree For A Cure

2024

07/02

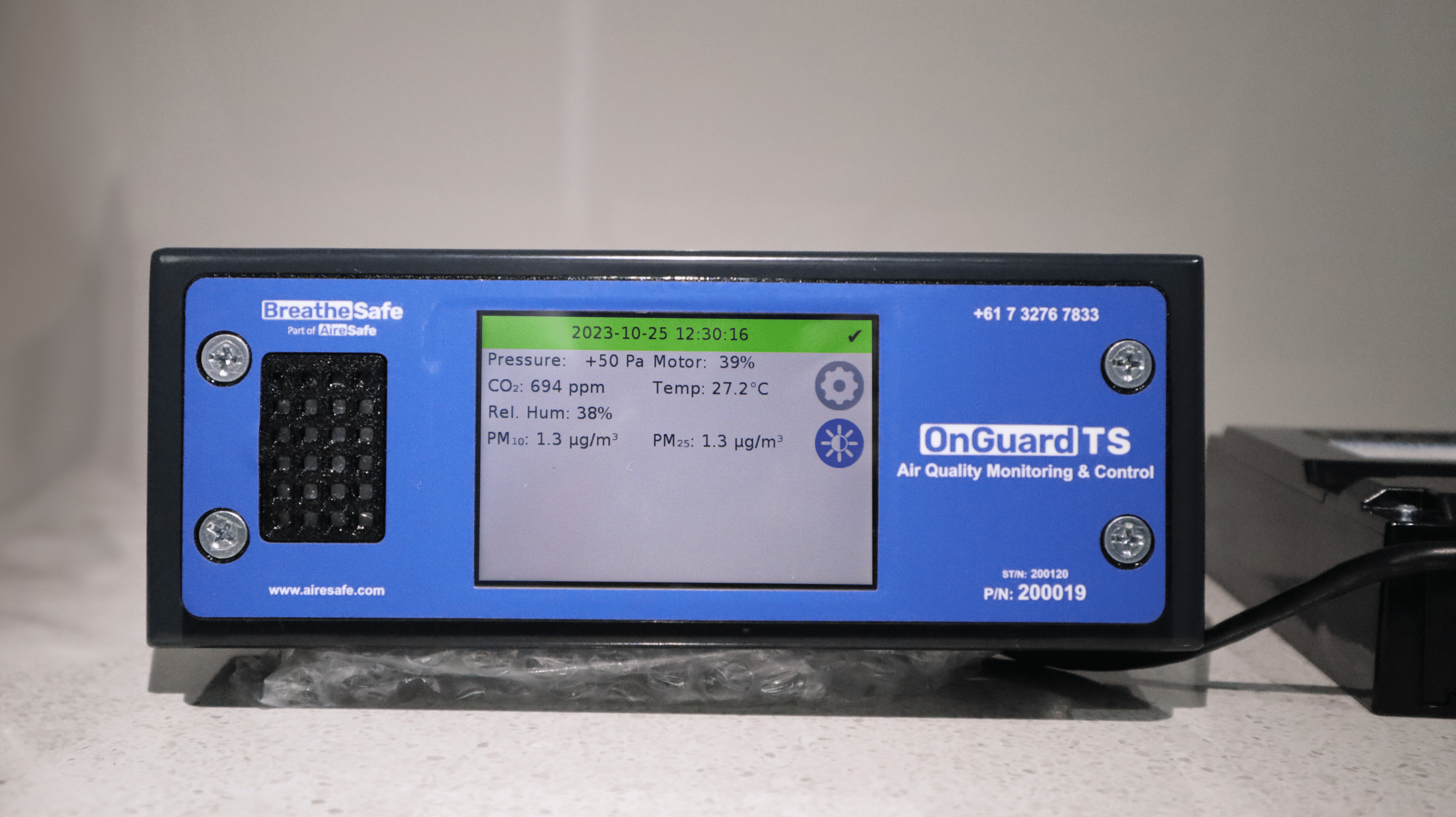

The Ultimate Air Quality Management System – OnGuard

2023

01/11

Demo Video – Motor Replacement for TL Air Pressuriser

2023

15/10

BreatheSafe Cares – MACA Cancer 200 Ride

2023

04/10

System Installation – Komatsu Excavator PC290LCi-11

2023

15/08

System Installation – Komatsu Wheel Loader WA250PZ-6

2023

13/07

Remote Air Quality Control by OnGuard Monitor & Controller

2023

13/07

Comply with ISO23875 – BreatheSafe Cabin Air Purification

2022

01/11

System Installation – Hitachi Haul Truck EH3500

2022

14/06

Industry Standards and Regulations

2021

20/12

Meandu Trial Cabinet Dust Prevention

2021

06/10

Meet and Exceed ISO23875 with INPRESS TS Controller

2021

20/09

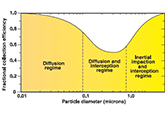

Five Common Misconceptions about Air Filters

2021

31/08

Data Monitoring: The Key to Success in Minimising Exposure to Dust

2021

26/07

BHP Autonomous Cabinet Field Trial

2021

06/06

RPME is the BEST PRACTICE to Stop Respirable Dust

2021

06/06

OEM Cabin Filters Were Not Designed to Stop Respirable Dust